The rolling inductor is used as a tool for heating a metal workpiece, specifically targeting a particular section of the material. The rolling inductor is chosen when precision, speed, efficiency, and focused heat treatment are required. This technology is particularly suited for industrial processes demanding high quality and consistent results. Want to learn more about using a rolling inductor for heat treatments? Read on.

The relationship between induction heating and the rolling inductor

A rolling inductor is a tool used to perform induction heating. Our induction heating system, one of our specializations alongside electrical equipment, offers versatile applications. The purpose of this system is to (pre)heat electrically conductive constructions. The induction heating system can also be used for annealing, hydrogen removal, post-weld heat treatment, and shrink-fitting applied to pipes and flat plates of various diameters.

Rolling inductor for induction heat treatment

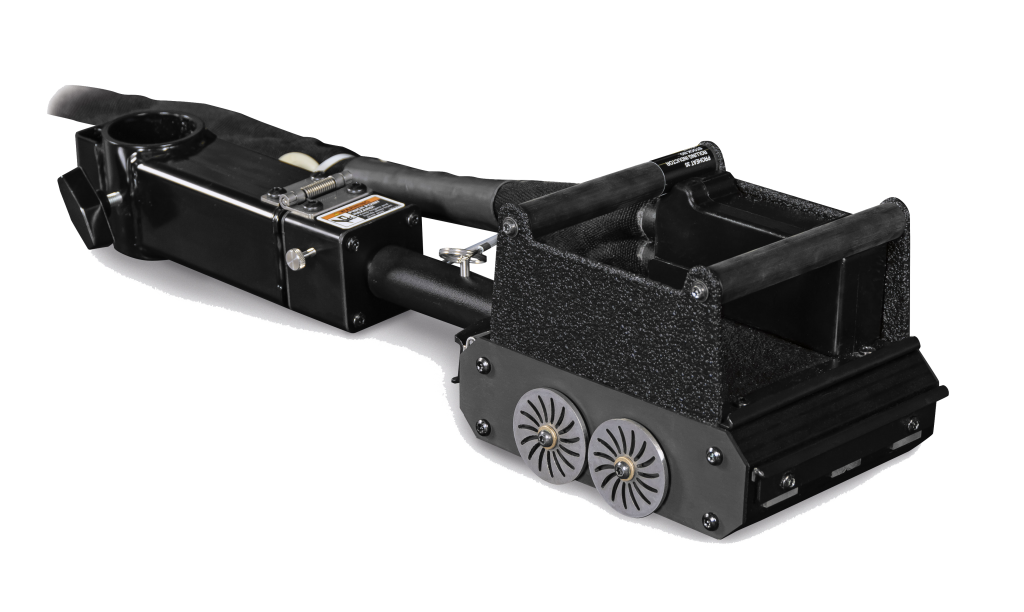

But what if a component is too large for the standard configuration? This is where the rolling inductor comes into play. This tool provides an effective solution for larger workpieces, ensuring that induction heat is applied efficiently and uniformly, making the system ideal for a wide range of industrial applications.

How is the Induction Heating System composed?

The system consists of several elements, starting with the Induction Unit System, powered by the ProHeat 35. This induction power source, with a built-in temperature controller, can run one or two heating cables simultaneously. The liquid-cooled system ensures fireproof operation, with the heating cables connected to the metal piece to complete the process. For larger components, we rely on our specialized tool: the rolling inductor, ensuring efficient and uniform heating even for oversized workpieces.

When do we use the rolling inductor?

We’ll use the rolling inductor for the larger metal pieces and moving parts. If we talk about bigger metal components, you can think about big tubes, larger pipes, pressure vessels, steel presses and other heavy constructions. The rolling inductor is a flexible and compact construction. This ensures that the set-up time and costs will be reduced. Because of the local heat input there it will lose as little power as possible. That causes rapid heating. The maximum temperature will be up to 315 degrees (600°F). It’s possible to connect 2 rolling inductors on one Proheat35. The power of 45Kw will be divided proportionally. If you want to connect two rolling inductors we can recommend using an external heat exchanger to improve the cooling process.

Delta Heat Services

Delta Heat Services was founded in 1997 and established their headquarters in Stellendam, The Netherlands. Delta Heat Services is a service aimed company. We are also qualified and experienced in heat treatment. Due to a high level of knowledge, years of experience and technology Delta Heat Services delivered numerous high profile projects worldwide. It’s possible to buy or rent our induction equipment. Read more about our induction equipment, and our other specializations.

We also work on project basis. Do you have a question about our services or do you want to request a quote? Please contact us and we’re happy to help you. We’re open 24 hours a day for support and advice for your projects. Delta Heat Services operates under the most current quality standards and certifications.