Do you want to know more about our heat treatment methods? One of our treatments is the post weld heat treatment. It’s based on welding the metal piece after welding. Discover more about our post weld heat treatment. As a heat treatment specialist we offer different heat treatments. Get to know more here.

What is post weld heat treatment?

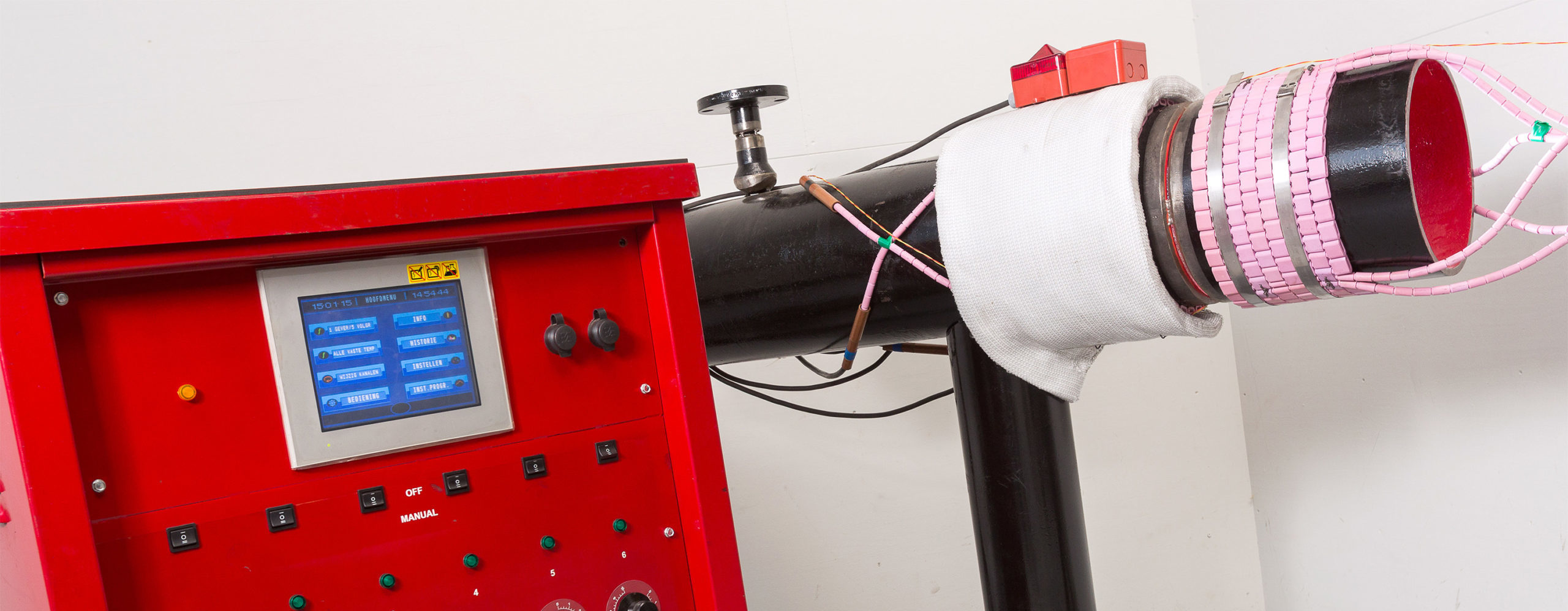

Post weld heat treatment (PWHT) is a regularly performed, controlled process in which an object is being reheated to a temperature below its lower critical transformation temperature. It is held at this specific temperature for a certain amount of time. This process is being done after the object has been welded. There’s also a possibility to treat the metal piece before welding. Take a look at our pre weld heat treatment.

The added value of a post weld heat treatment

The added value of a post weld heat treatment is that it will retain the strength of a metal piece. It will reduce residual stresses by heating the material to a specific temperature and then gradually cooling it. Moreover, it prevents hydrogen induced cracking from happening by post heating the object immediately after completion of the weld. Besides, it will enhance material strength and the treatment can also function as a method of hardness control. For example; within the different industries of oil, gas and petrochemicals, it is mandatory to ensure a safe design. Post weld heat treatment is a form of establishing those mechanical properties.

Incorrect use and requirements

When PWHT is being performed incorrectly, residual stresses can exceed the material its design limitation leading to welding failures, cracking potential and increased chance on fractures. Whether an object should undergo PWHT and how long the treatment should last, depends on the alloying system, previous undergoing treatments and the materials the object is made of.

Post-weld annealing

One of our heat treatments that falls under post weld heat treatment is post-weld annealing. This is applied when it is important to soften the metal piece and reduce internal stresses. The welded workpiece is heated to a specific temperature. This temperature is typically lower than the melting temperature of the base material, but high enough to achieve the desired microstructural changes. Ultimately, the goal of post-weld annealing is to normalize the microstructure of the metal. Other heat treatments that fall under post weld treatments include stress relieving, normalizing, and, for example solution annealing.

About us

Delta Heat Services is a qualified and experienced specialist in heat treatment. Next to that, are we specialized in preheating, annealing, post weld heating, bake- and dry-outs and shrink fittings. We offer a broad range of services and combine our knowledge with technologies. Also, we offer a good service as we are flexible and customer-oriented. We want to provide the best solutions for every heat treatment enquiry. Delta Heat Services operates internationally and is located in the Netherlands, Portugal, Romania and the Caribbean. Are you interested in the heat treatments services of Delta Heat Services? Please get in touch with us.