Did you know that the strength of steel can change in a negative way after welding? During welding, the steel is locally heated to a high temperature, which can change the microstructure of the steel. Heat treatment aims to prevent or eliminate problems resulting from welding. Annealing is one of those heat treatments and it can prevent stress in the material around the weld seam. Stresses in the material can unintentionally cause cracks in the steel. Annealing steel ensures that stress is kept to an absolute minimum. Read on to learn more about annealing welds and the benefits of this technique.

The process of annealing steel

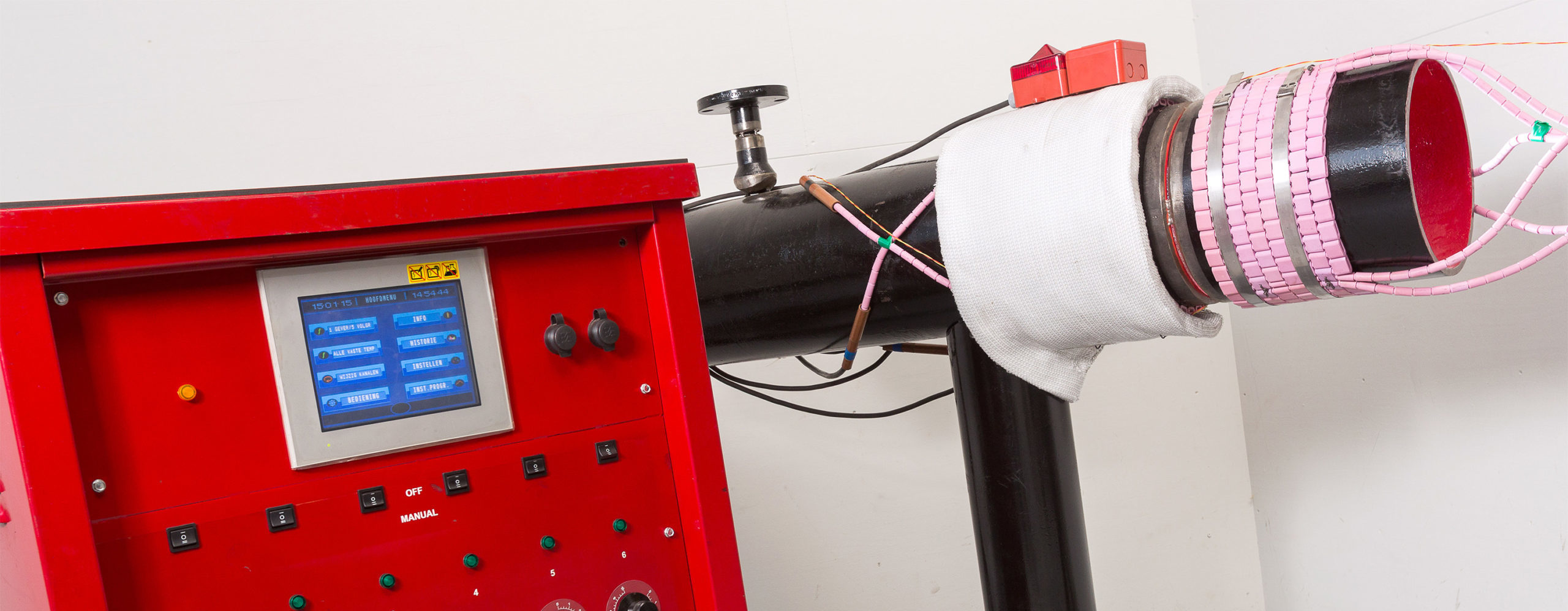

As already mentioned, annealing steel can avoid stresses in the material. Another benefit is that annealing can reduce hardness and improve workability. Annealing occurs at the end of the welding process and is also referred to post weld heat treatment (PWHT). It is done after the welding process to improve the properties of the weld. Depending on the material and usage of the workpiece, we work with different heat treatment procedures according to client standards. During the welding process a high temperature is experienced in the weld and parent metals.

This exposure can lead to significant variations in the microstructure of the material, affecting its overall strength and integrity. To counteract these changes and ensure the weld area and surrounding material return to a condition that is as close as possible to their original state, annealing is implemented.

Heat treatments besides annealing steel

Besides annealing steel, there are also other methods that belong to the heat treatment of steel. We also offer heat treatments like normalizing, stress relief, post-weld and pre-weld heat treatments. We’ll explain you the different heat treatments:

- Normalizing: this process is similar to annealing. Normalizing involves heating a material to a specific temperature and then allowing it to cool in still air. This treatment refines the grain structure and improves mechanical properties.

- Stress relieving: this heat treatment is performed to reduce internal stresses within a material, typically after machining or welding.

- Post-weld heat treatment: this heat treatment is performed to imnprove the properties of the weld after the welding process, almost the same as the annealing process.

- Pre-weld heat treatment: pre-weld heat treatment is sometimes performed on materials with high hardness to make them more amenable to welding. This helps prevent cracking during welding.

Is there a big difference between annealing steel or other metals?

The basic principles of annealing—such as heating to a specific temperature, maintaining that temperature for a period, and then cooling at a controlled rate—are similar across different metals. However, the specific temperatures, cooling rates, and atmospheres can vary significantly from one metal to another. For example, the annealing process for steel involves temperatures typically ranging from 600°C to 700°C, while for copper, the annealing temperature might be around 400°C to 600°C.

In summary, while the fundamental concept of annealing is consistent across different metals, the specific procedures, temperatures, and outcomes can vary significantly depending on the type of metal being annealed. Therefore, there can be a significant difference between annealing different types of metals, including steel, in terms of technical details and material responses.

Delta Heat Services: your annealing specialist

The bottom line is that the heat treatments, like annealing steel, are dependent on the type of material that’s been welded and the intended use of the finished workpiece. We will discuss the best choice of heat treatment. So we can determine the best way according to our expertise and customer needs. This ensures that the final product not only meets the required specifications but also maintains its quality and durability over time.

Delta Heat Services mainly focuses on the execution of heat treatments for the industry. We offer a wide range of services and possibilities. We have the knowledge and the technology to offer you the heat treatment solution you are looking for. Are you curious about the possibilities of Delta Heat Services? Or would you like to know more about the annealing process? Please contact us. We are happy to answer your questions and look at the possibilities together.