At Delta Heat Services, we define preheat as the preheating of parts during welding. When we use this depends on a number of factors. For example, we usually use it when working with critical (hardenable) materials. We are happy to explain how the preheat process works and when and why we use it. We answer all your questions. Does an urgent question remain unanswered? Do not hesitate to contact us without any obligation. We are happy to help you find a suitable solution.

What’s the definition of ‘preheat’?

Preheat, or the preheating of metals, is a crucial process in industrial applications such as welding and heat treatment. It helps reduce stress within materials and prevents cracking both during and after welding. Preheating contributes to higher quality and durability of metal connections.

The positive results of a preheat treatment

Ultimately, a preheat treatment reduces the risk of undesirable microstructures in the metal. This includes hardness zones, which can negatively affect the strength and lifespan of the material. The process plays a vital role in demanding sectors such as the oil and gas industry, shipbuilding, and heavy construction, where reliability and precision are of utmost importance. By carefully applying preheat techniques, not only is the technical quality improved, but operational efficiency is also enhanced.

Determining factors for the use of preheat

Preheat is actually the preheating of parts during welding. However, a number of factors determine whether it is necessary to preheat. We usually perform preheat on critical (curable) materials. The carbon content and alloying elements cause hardness and stress in the material during welding. This can largely be prevented by using preheat. Another factor that can influence the process is the material thickness. The amount of heat input can slow the cooling of the weld.

How does a preheat process work?

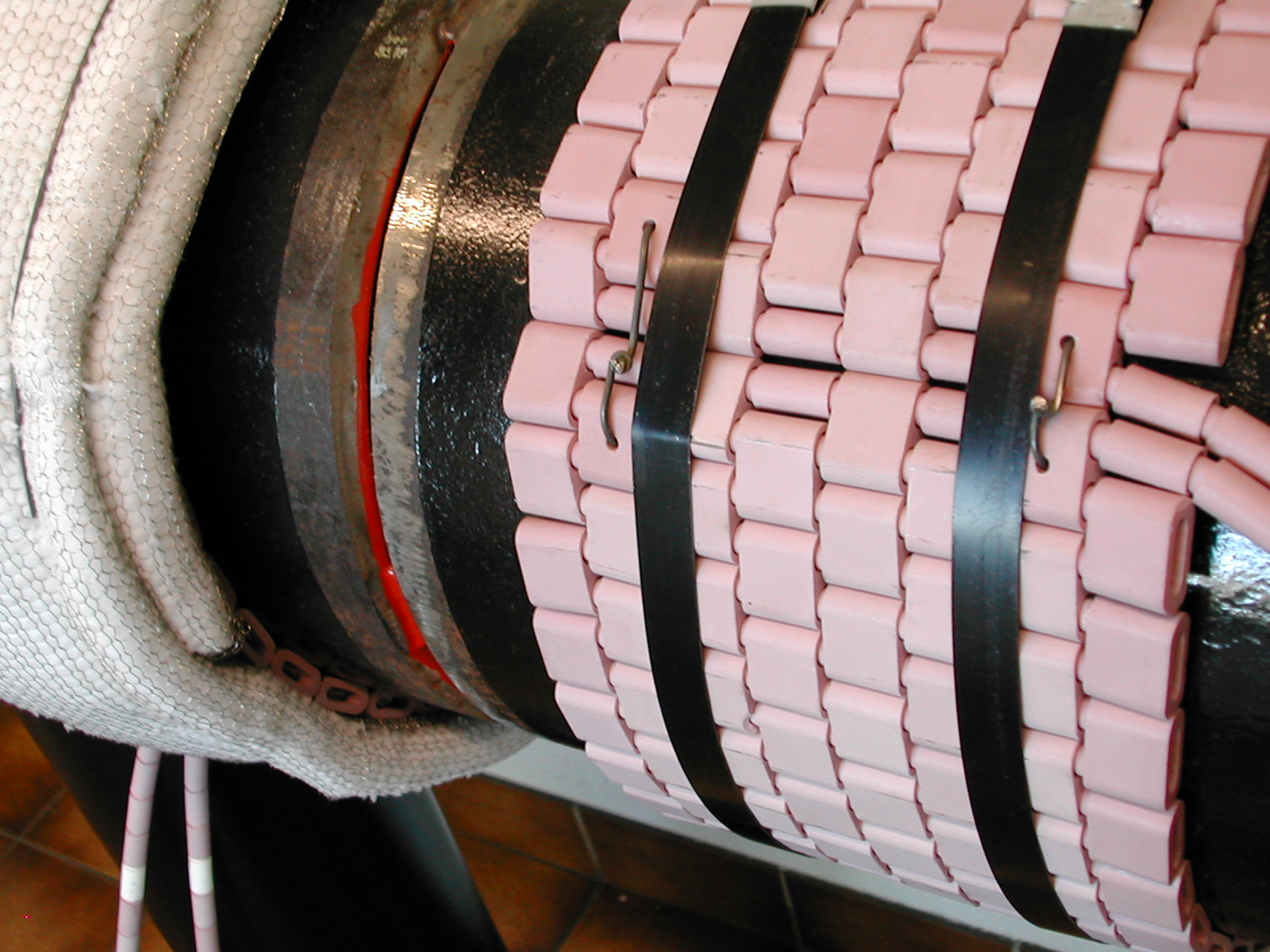

How exactly does the preheat process work? A homogeneous temperature is obtained by means of induction heating or with resistance elements (meshes) that are attached to both sides of a weld seam to be taken. As a result, the welds are brought to the same temperature over the entire length of, for example, a pipe. We therefore also call this process of preheating preheat.

When and why is preheat used?

Depending on the required procedures that are expected from a client, there are various factors that determine whether preheat is used. This often differs per situation, so we advise you to contact us without obligation. Then we can make an estimate that is tailored to your question. Preheat is primarily used in sectors such as shipbuilding, offshore, and heavy construction. It helps prevent metal fatigue and improves the weldability of alloys. At Delta Heat Services, we have extensive experience in applying this technique to complex projects.

Due to the delayed cooling speed during the welding process, preheating allows you to achieve less hardness, less stress and less structure change of the material. Deformations of the material can also be largely prevented. Depending on repairs to the weld seam, cracks, slag inclusions and bonding errors, preheat is again required.

Request a quote

Can we serve you with preheat or any of our other services? Or do you have a (number of) question(s) to which we can answer? Please contact us or request a no-obligation quote right away. We are happy to help you find a suitable solution.